English version

The French version of this projet is more up to date. Please refer to that version while the translation is in progress.

In the context of the pandemic of SARS-CoV-2 I've been actively working on a design of foldable head shield that could be produced in large quantities. In this post I provide all the details about this project, including the blueprints and production instructions for makers.

This project is about producing foldable head shields for protecting the face of anyone who may be in contact with patients. The head shields are made of a transparent plastic sheet pre-cut in one piece and are shaped by the end user by a simple folding.

Two types are available:

Type A : without mask |

Type B : in addition to a mask |

|

|

|

|

Why foldable shields ?

Face protection is a major issue in protecting people who may be in contact with patients. Standard masks covering the nose and mouth do not protect the eyes, skin or ears, which can be pathways for pathogens. Some commercially available shields exist, but in the context of the current pandemic the stocks and production capacities are insufficient to meet the very high demand. It can be estimated that, in France, the number of persons that are highly likely to come into contact with SARS-CoV-2 patients is between 500,000 and 2,000,000, which represents between 0.7 and 3% of the population (carers in hospital, general practitioners, pharmacists, paramedics, stretcher bearers, pumps funeral, maintenance officers, vigils, homeless volunteers, etc.).

Many makers and companies are already using additive manufacturing to print hoops on which a plastic film and an elastic band can be attached to form a head shield, mostly on the basis of the design developed by Prusa. A large network quickly formed in France on resistancecovid.com and a production protocol has been defined in collaboration with Parisian hospitals (APHP).

This approach, however, has difficulty finding a large-scale impact since on the one hand 3D printing is slow (at least several tens of minutes per part for recent models, plus a manual deburring phase of the parts), and on the other hand the distribution of production agents raises many questions related to the availability of raw materials, the collection, quality control, assembly and sterilization of the items. Despite the large amount of energy currently injected into this manufacturing process, the production chain on the French scale is unlikely to exceed a few tens of thousands of copies per day.

This project offers a different and complementary approach. The challenge is to simplify the manufacturing and packaging process as much as possible to allow local production of several hundreds (for makers) or tens of thousands (for manufacturers printing professionals) of units per day. For this I use only a single raw material and a single machine, no assembly and a simple packaging method allowing both the degradation of possible viruses and an easy distribution to the end users. If the process can be replicated at the level of printing professionals, who have high-throughtput machines, mass production could be achieved in a short period of time. Despite its high potential, no similar action has been identified yet.

In the longer term, the very low cost of this technology and the advantages it has in terms of storage and distribution means that it can also be used in the fight against other epidemics, especially in countries with few means.

Foldable shields

The folding patterns have been designed and optimized at the Jean Perrin Laboratory (Sorbonne University, Paris, France) on the basis of the standard A4 format. Type A uses the sheet in portrait, while type B uses it in landscape. The designs are distributed under the free license Creative Commons CC-BY 4.0. The strength of each attachment point has been tested to prevent tearing.

So far, only a few dozen samples have been produced with a semi-professional cutting machine (Graphtec CE-6000-40).

Once the patterns have been cut, they simply need to be packaged in packs of 20 in standard envelopes. These pouches, once sealed, are placed in an oven at 70°C for 30 minutes to remove any viral load. Even if this procedure has not yet been validated specifically for SARS-CoV-2, it is effective on known coronaviruses ( link and link).

These head shields have been designed for single use only. Tests may nevertheless be conducted later to consider re-use after disinfection.

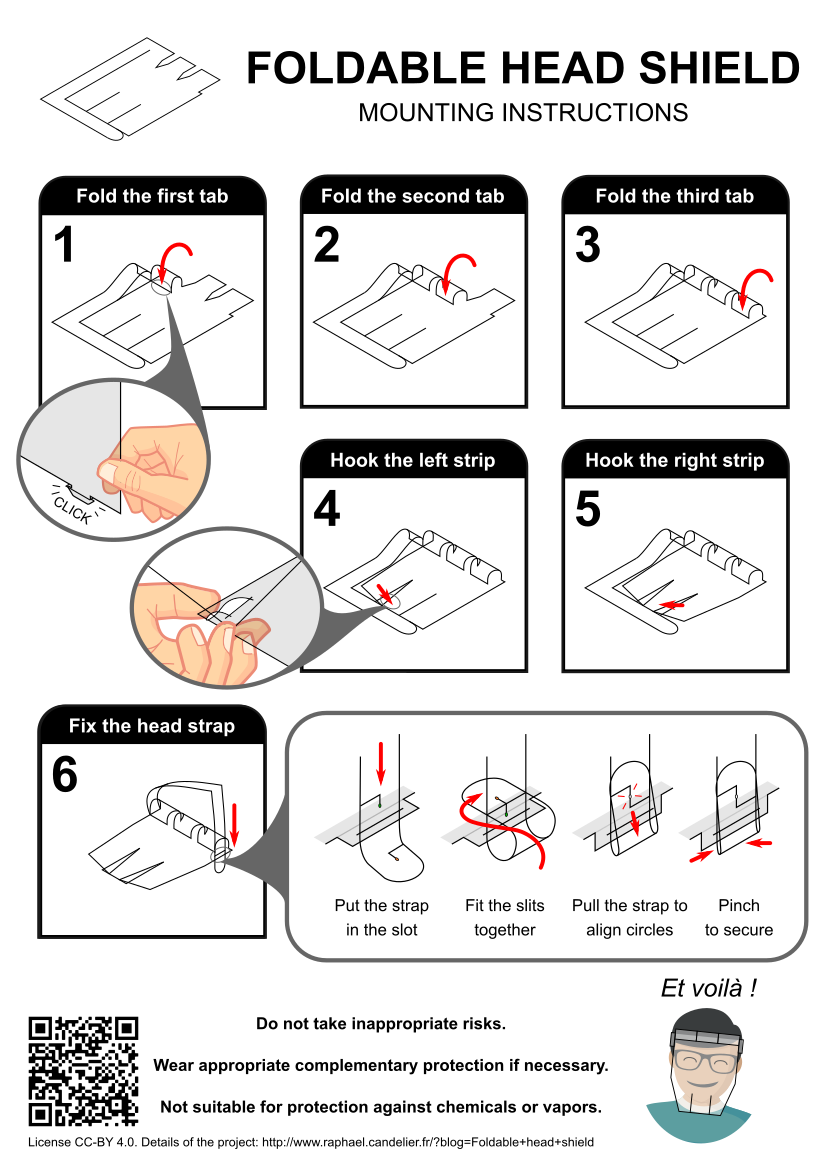

Finally, engravings on the pattern give rudimentary folding instructions, and an illustrated folding notice has been created in French and English:

How to produce it locally ? (for makers)

Anyone can produce these head shields provided they have a cutting machine and transparent plastic sheets.

Cutting machine (plotter)

For this project I used a mechanical vinyl cutting machine, also known as a plotter. Plotters range from very simple and affordable models (around 150 USD) used mainly to cut paper up to professional machines (between 5 to 10,000 USD) mainly used for cutting vinyl in the production of stickers (Graphtec being a reference constructor). Plotters can be found in creative hobby workshops or some fablabs.

A CO2 laser cutting machine can also be used, as in this project for example. However, even if the cutting is rapid, the limiting point of the manufacturing process is the placement and removal of material in the machine. Also, not all plastics can be used and one should favor PMMA (also called acrylic or plexiglass) or PET (from the polyester family). In any case an adequate filtering and ventilation system is absolutely necessary .

Plastic sheets

Any sheet of rigid plastic shoudl work. Sufficient rigidity generally appears when the sheet is more than 100µm thick. Overhead projector transparencies (often made of cellulose acetate) work well and are already in A4 format. On the other hand their optical qualities (transparency, color) is usually bad, especially for transparencies suitable for inkjet printing which have received a specific surface treatment. Transparencies intended for manual writing are therefore to be preferred. The plastic sheets provided for the binding of reports (typically PVC or PET) can also be used.

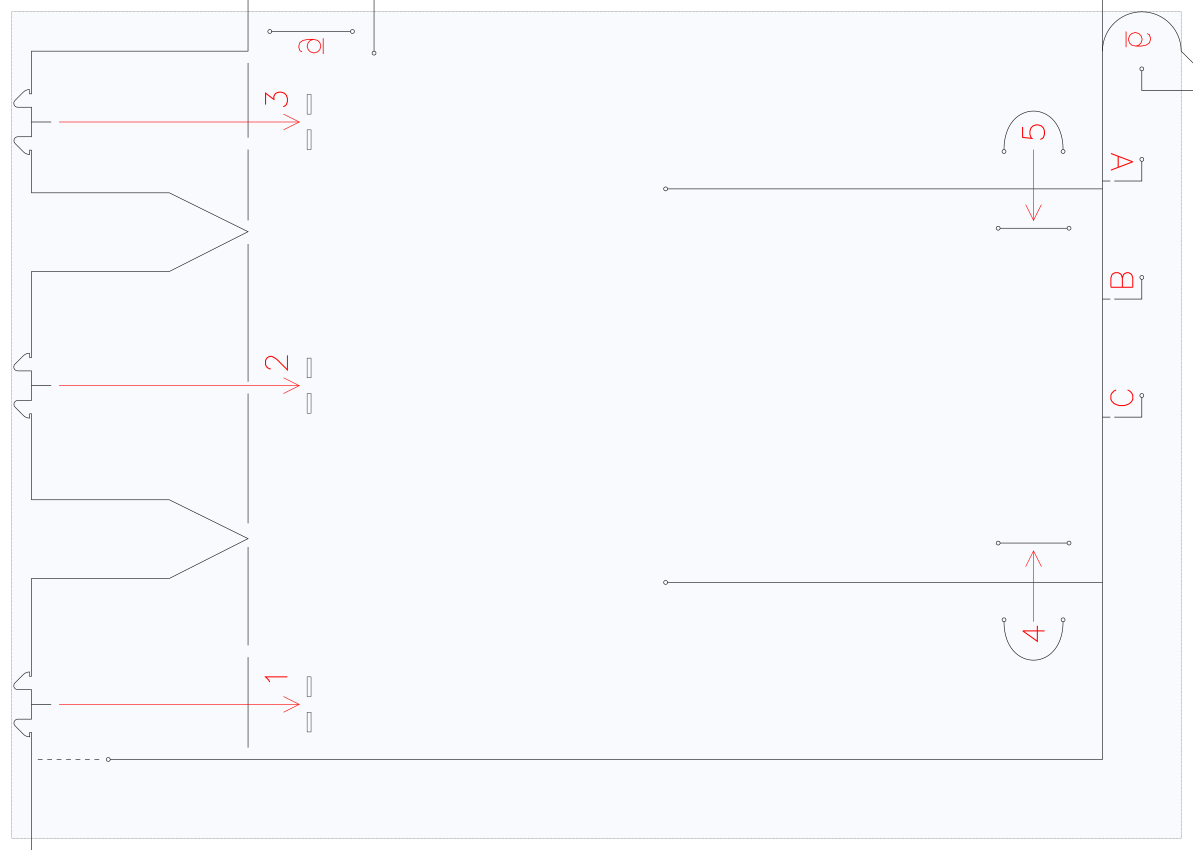

Cutting process

The cutting file (in .dxf format) is provided in the "Downloads" section at the bottom of the page. Adjustments will no doubt be necessary depending on the machine used. The force applied to the blade must be adjusted so that the paths in red do not perforate the sheet but make engravings between 10 and 50% of the thickness; these marks are simply guides for folding and can optionally be removed. The paths in black must be cut out entirely.

It is necessary to use an adhesive protective mat in order not to damage the machine. These rugs can be made yourself by covering fine cardboard with tape, then by spraying glue and letting to dry for 30 minutes. One then has to add two strips of tape at the rollers' level to protect it from the glue.

Packaging and decontamination

The patterns fit in standard envelopes in A4 format (reference). You must also add an A4 sheet containing assembly instructions, which you will find in the downloads below.

Once sealed, the pouches should be decontaminated in an oven at 70°C (158°F) for 30 minutes. Generally speaking, wearing gloves and a mask during the manufacturing and distribution process is highly recommended.

Acknowledgments

This project has been funded by a crowdfunding campaign (4.7k€) that allowed an immediate start for testing and production, followed by a grant from the Faculty of Science and Engineering at Sorbonne University (75k€ for several projects for the Fablab at Sorbonne University and the Polytech Institute).

I would like to warmly thank all the donors, but also Christophe Travert (resident at the Institut Mutualiste Montsouris) for his tests in real conditions and suggestions for improving the design, Maxime Deforêt (CNRS researcher) for his efficient search of information, André Estevez-Torres (CNRS researcher) and Ghislaine Morvan-Dubois (CNRS researcher) for logistical assistance.

Downloads

The sources and cutting files of the latest versions are accessible below. For a small production you can use the version adapted to pre-cut sheets in A4 format, and for a larger production you can use the version adapted to the material rolls.

Type A |

Type B |

|

A4 |

||

Roll |

Folding intructions:

English: Instructions_EN.pdf

French: Instructions_FR.pdf

Happy making, and take care!

Comments

There are 3 comments on this post.